Foxwell JT600

6 Cylinder GDI, EFI, FSI Fuel Injection Systems Piezo Ultrasonic Fuel Injector Cleaner Test Cleaner Kit

One Year Warranty

One Year Warranty Lifetime Free Update

Lifetime Free Update 1-5 Days Shipping

1-5 Days Shipping Lifetime Tech Support

Lifetime Tech Support

Foxwell JT600 Description

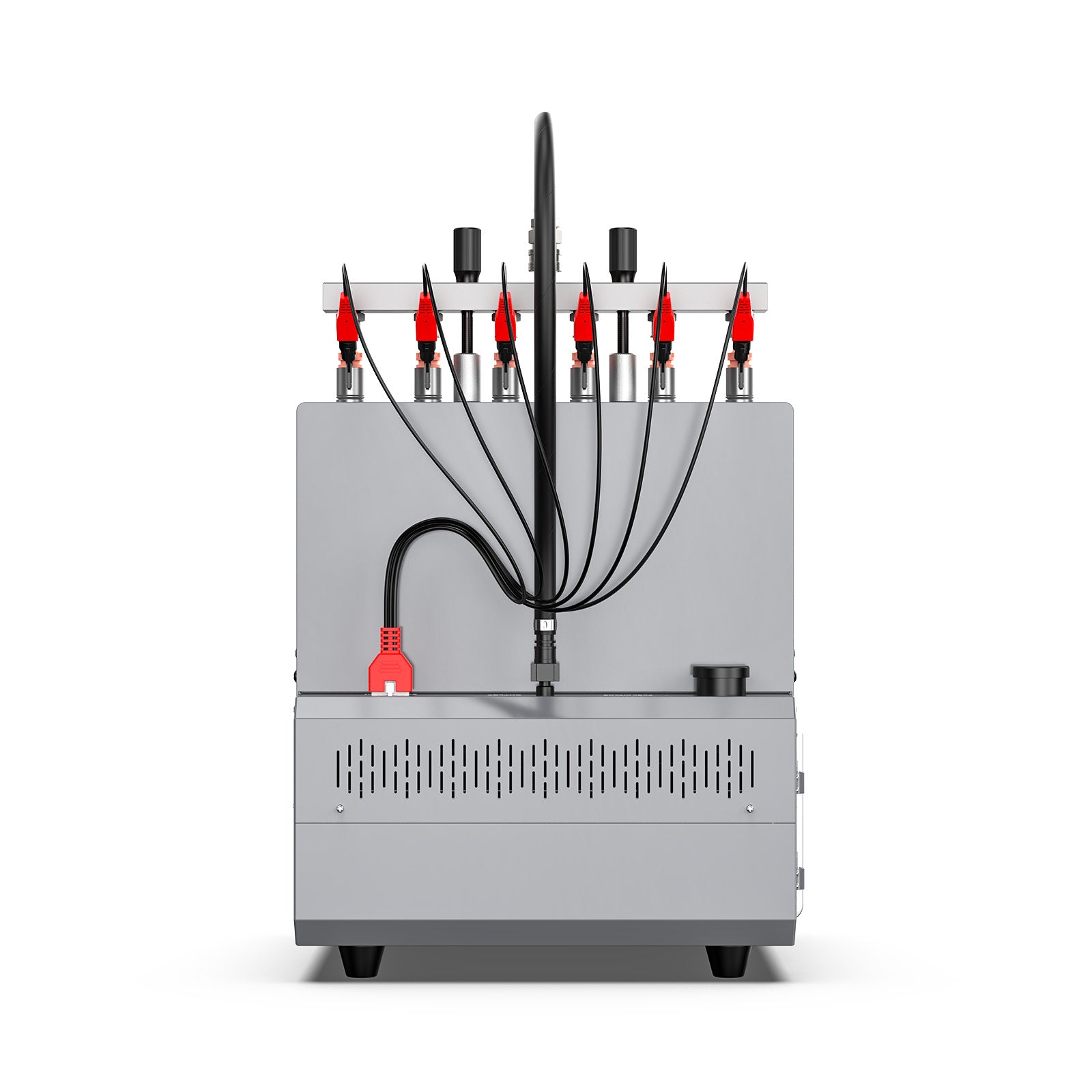

FOXWELL JT600 GDI Piezo 6-cylinder Fuel Injector Cleaner & Continuous Injection Tester. JT600 GDI Piezo adapts the latest GDI design, which also supports the continuous test function of the fuel injector. It can clean and test standard injectors, EFI, FEI, Piezoelectric fuel injectors, as well as GDI injectors, such as for Mercedes-Benz, for BMW, for Audi, for Porsche, for Ford, and other direct injection engines. It comes with multiple voltages available for GDI injectors, enabling adaptation for different injector testing types. The machine is the necessary and preferred equipment for the automotive service and maintenance, research, and training departments. It has a smart display screen. Support for more cars and motorcycles. It can only be used to clean diesel fuel injectors.

Why Need FOXWELL JT600 GDI Piezo Fuel Injector Cleaner & Tester?

Why Need FOXWELL JT600 GDI Piezo Fuel Injector Cleaner & Tester?

The performance of the injector plays a vital role in the power of each engine. Due to the fuel quality, the injector cannot work normally, causing serious carbon deposits in the cylinder; accelerating the cylinder bore and piston ring, causing unstable idling, increased fuel consumption, weak acceleration, difficulty in starting, excessive emissions, and complete blockage of the injector. Cause damage to the engine, so the injector should be cleaned regularly.

JT600 GDI Piezo Injector Cleaner & Tester Main functions:

- Ultrasonic cleaning: To clean the injectors to obliterate the carbon deposition on them.

- Resistance test: To test the resistance of the fuel injector.

- Uniformity / Sprayability test: To test the uniformity of the injection amount of each injector, and to monitor the spraying status of each injector with the help of a backlight.

- Leakage test: To test the sealing and dribbling conditions of injectors under system pressure.

- Injecting flow test: To check the amount of the injector in 15 seconds of constant injection.

- Auto. test: To test injectors by preset program conditions.

- On-Vehicle Cleaning: Coming with a variety of disassembly-free cleaning connectors, the device can be used to perform on-vehicle cleaning and maintenance for various vehicle models.

- Low resistance injectors test function: Through the dedicated motherboard, it supports the full and long test of low-resistance fuel injectors, such as 1 Ohm.

- Multi-item Setting: Set different parameters of the device, including the buzzer sound level, display brightness, and backlight brightness.

- Version information: To check the software version information of the current device

JT600 GDI Piezo Main Features:

- This device supports the cleaning and testing of Piezo injectors, GDI injectors, and traditional injectors.

- The special structure design makes the disassembly and assembly of the fuel separator easier and greatly improves the work efficiency.

- With the resistance test of the injectors one by one, get to know the condition of the injectors.

- With the dedicated motherboard, it can support the full and long test of low-resistance fuel injectors, such as 1 ohm.

- The unique fuel circuit depressurization technology can make the machine automatically depressurize in the case of sudden shutdown, avoiding equipment damage or personal injury.

- The back door of the cabinet opens or closes with one touch.

- The brightness of the screen and backlight, and the level of the buzzer, can be manually set and saved.

- The machine has a strong ultrasonic cleaning ability, which can remove carbon deposits and impurities on the fuel injection nozzle to the greatest extent.

- The product adopts fuel pressure adjustment and control technology by microcomputer, which can ensure stable fuel pressure and a wide adjustable range. It applies to vehicles equipped with a variety of gasoline injection systems. Meanwhile, the automation of the injectors’ cleaning and testing processes can be realized.

- Thanks to the adoption of microcomputer automatic control and digital display technologies, the cleaning and testing processes can be controlled automatically, and the parameters of the main status can be monitored in real time.

- Automatic fuel drain during a certain test can be realized via a routine, owing to the adoption of automatic fuel drain control technology. Start or [Stop] fuel drainage via the [Drain] button on the control panel in running or stop state.

- Adopting a humanization design can make the system pressure fast restored to the default values.

It is an expert in injector solutions, featuring 11 injector-specific functions.

- Ultrasonic cleaning: It sends signals to the injectors through the pulse signal line, using the cleaning fluid with the ultrasonic vibration so as to completely remove the carbon and impurities inside the injectors.

- Idle speed test (0-20ms): Simulate the engine idling speed and test the state of the fuel injector.

- Medium speed test (0-7.5ms): Simulate the engine running at medium speed and test the state of the fuel injector.

- High-speed test (0-4ms): Simulate the high-speed performance of the engine and test the state of the fuel injector.

- Acceleration test: Simulate the acceleration state of the car and test the performance of the fuel injector.

- Shift speed test: Simulate the shifting state of the car and test the working performance of the fuel injector.

- Leakage test: Test the sealing condition of the fuel injector.

- Idle Speed Sprayability Test: Simulate the engine idling state and test the spraying performance of the fuel injector.

- Medium speed sprayability test: Simulate the engine medium-speed state and test the spraying performance of the fuel injector.

- High-speed sprayability test: Simulate the high-speed state of the engine and test the spraying performance of the fuel injector.

- Main unit information: used to store the product number and the date of manufacture of the product.

Specifications:

Packing List: