Foxwell JT400

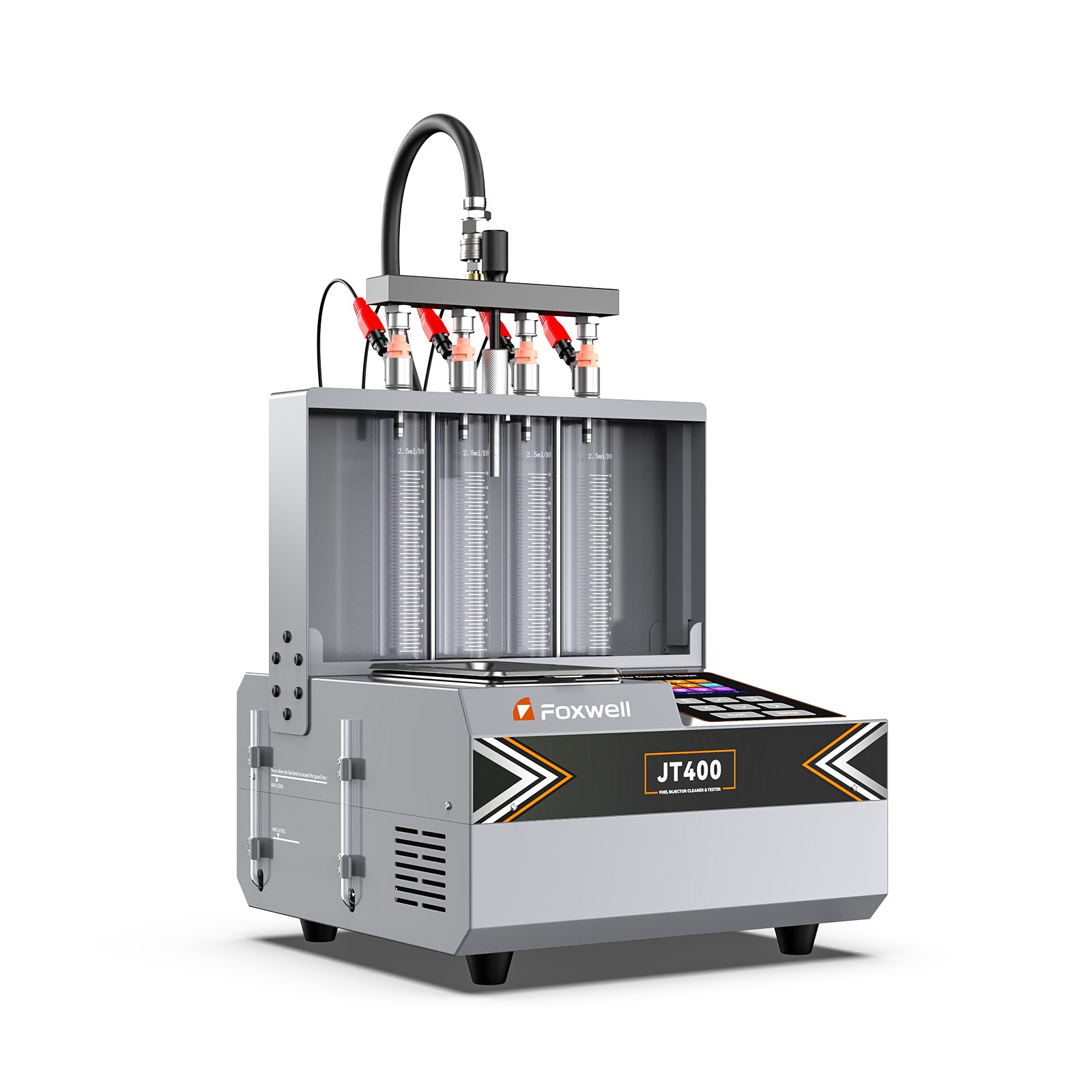

Fuel Injector Cleaner, Ultrasonic Cleaning Machine with Heating Function 4 Cylinder for GDI, EFI, FSI Fuel Injectors

Lifetime Free Update

Lifetime Free Update One Year Warranty

One Year Warranty 1-5 Days Shipping

1-5 Days Shipping Lifetime Tech Support

Lifetime Tech Support

Foxwell JT400 Fuel Injector Cleaner

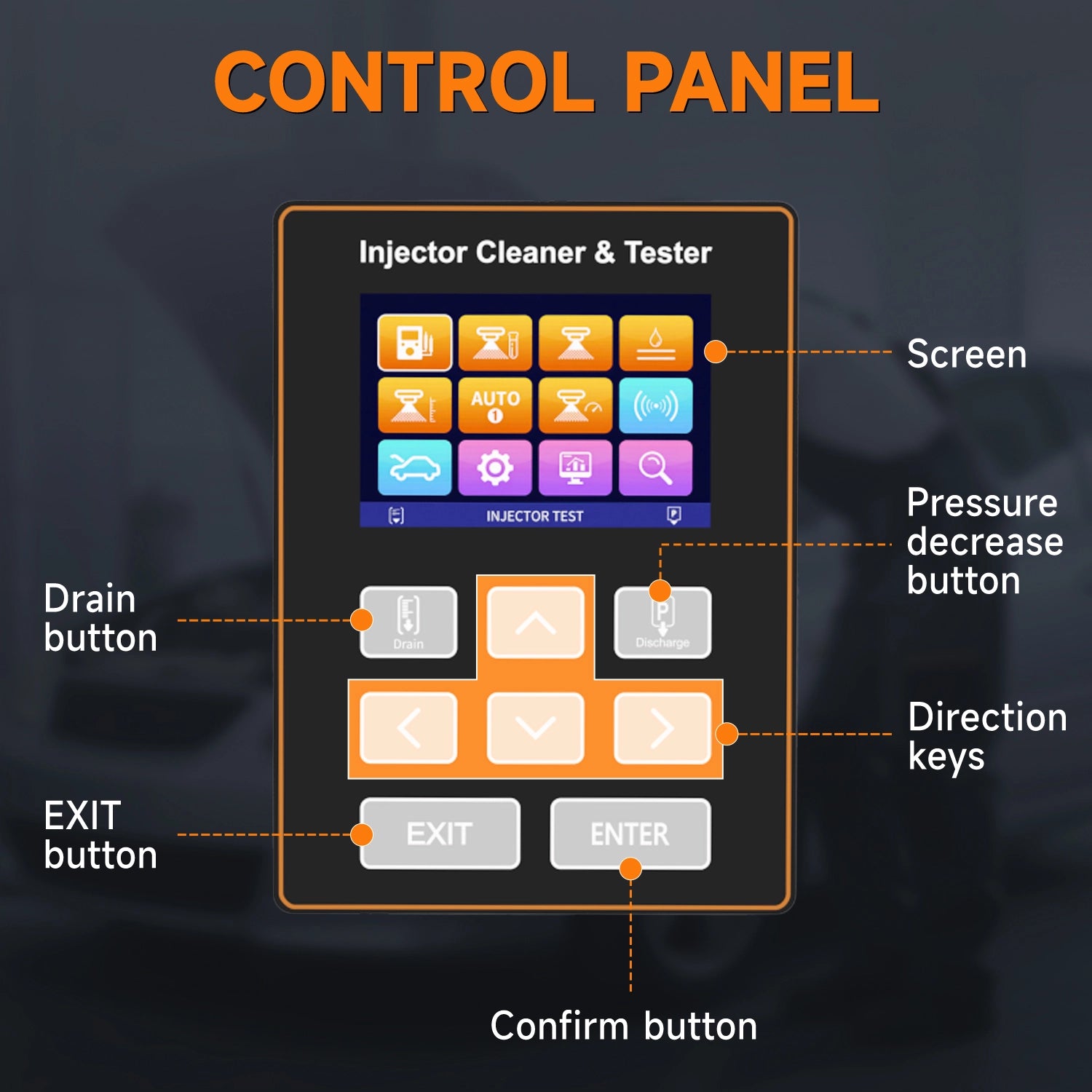

Foxwell JT400 is a professional 4-cylinder ultrasonic fuel injector cleaner and tester for both GDI (Gasoline Direct Injection) and traditional EFI injectors. It performs various tests, including uniformity, sprayability, and leakage, and features automatic modes, a colorful LCD screen, and a database for testing. It also offers on-vehicle cleaning for a complete cleaning solution.

Notice: This product supports 99% of petrol injector cleaning and testing. However, for diesel injectors, it only supports cleaning and not testing.

- Injector Test : Detect solenoid injectors resistance.

- UNIFORMITY TEST: Inspect fuel injection of each injector by observing its uniformity.

- SPRAYABILITY TEST: Inspect atomization of each injector by observing.

- LEAKAGE TEST: Inspect the sealing conditions of the injector needle valve under system pressure and to find out the injector with oil droplet.

- INJECTION TEST: Inspect injecting volume in 10 seconds meets the design specifications.

- AUTO MODE test : Inspect the injectors according to the established program1 of the equipment.

- VARIABLE SPEED TEST: Inspect the injectors in variable speed conditions.

- ULTRASONIC TEST : Clean the carbon deposits inside the fuel injector through ultrasonic.

- ON-VEHICLE CLEAN : Cleaning the engine fuel supply pipeline, injector, and combustion chamber with the machine does not require disassembling.

If your vehicle experiences poor fuel efficiency or rough idle due to dirty injectors, ultrasonic cleaning can remove the carbon buildup and restore the injectors to proper functioning, improving fuel efficiency and engine smoothness.

Usage steps:

- Pour in the injector detergent and place the injectors in the ultrasonic cleaner tank.

- Connect the pulse signal wire and select the ultrasonic cleaning function to start working.

Injector cleaning involves using chemical cleaners or physical methods to clean both the internal and external parts of fuel injectors. This can be done manually or with specialized equipment, typically involving soaking the injectors, injecting cleaning fluids, and testing their performance.

Usage steps:

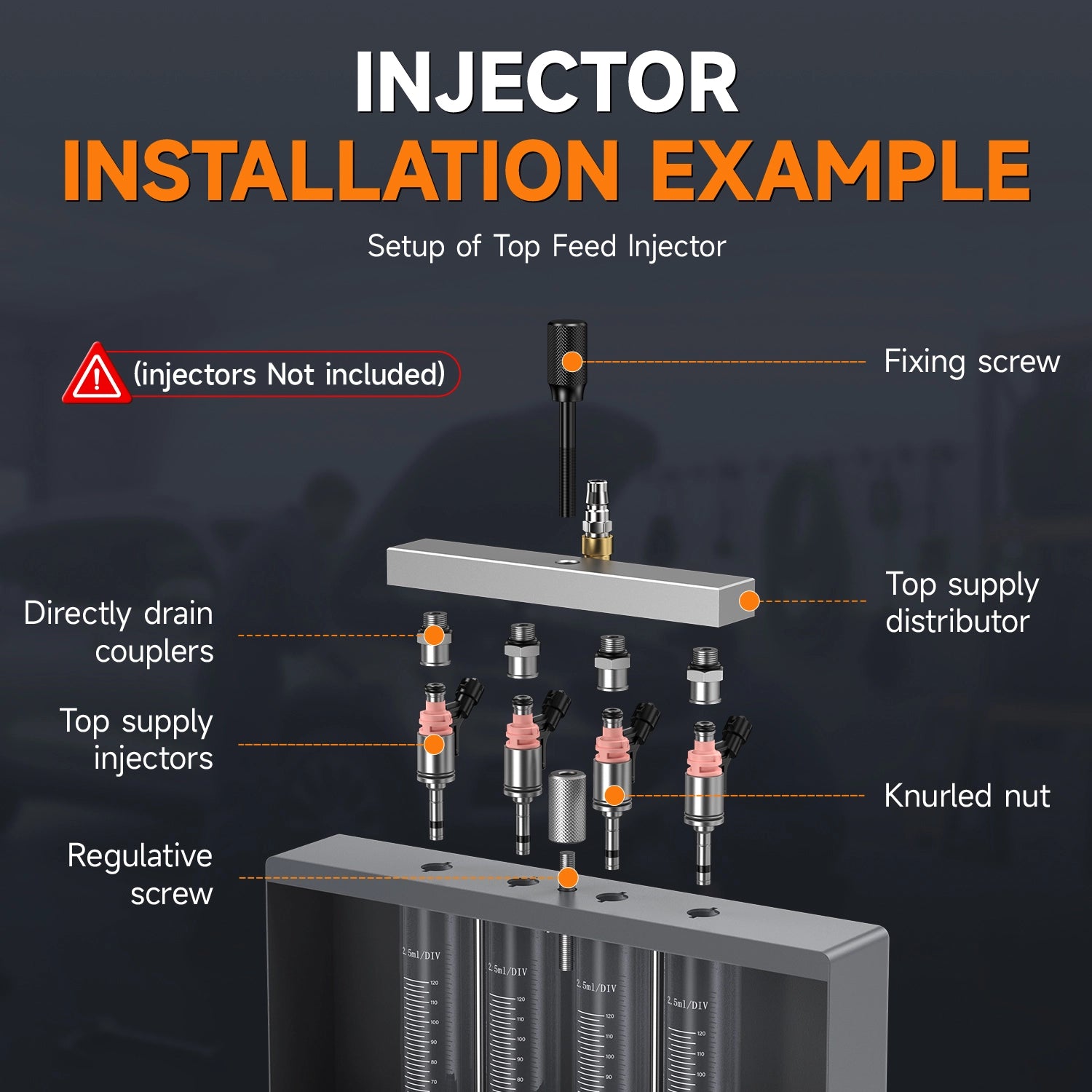

- Pour in the test liquid, install the fuel injector to the fuel distributor, and fix the main unit body.

- Test if the injector is leaking or blocked under different functions.

If your vehicle experiences poor fuel efficiency or rough idle due to dirty injectors, ultrasonic cleaning can remove the carbon buildup and restore the injectors to proper functioning, improving fuel efficiency and engine smoothness.

Usage steps:

- Pour in the injector detergent and place the injectors in the ultrasonic cleaner tank.

- Connect the pulse signal wire and select the ultrasonic cleaning function to start working.

Injector cleaning involves using chemical cleaners or physical methods to clean both the internal and external parts of fuel injectors. This can be done manually or with specialized equipment, typically involving soaking the injectors, injecting cleaning fluids, and testing their performance.

Usage steps:

- Pour in the test liquid, install the fuel injector to the fuel distributor, and fix the main unit body.

- Test if the injector is leaking or blocked under different functions.

Other Functions

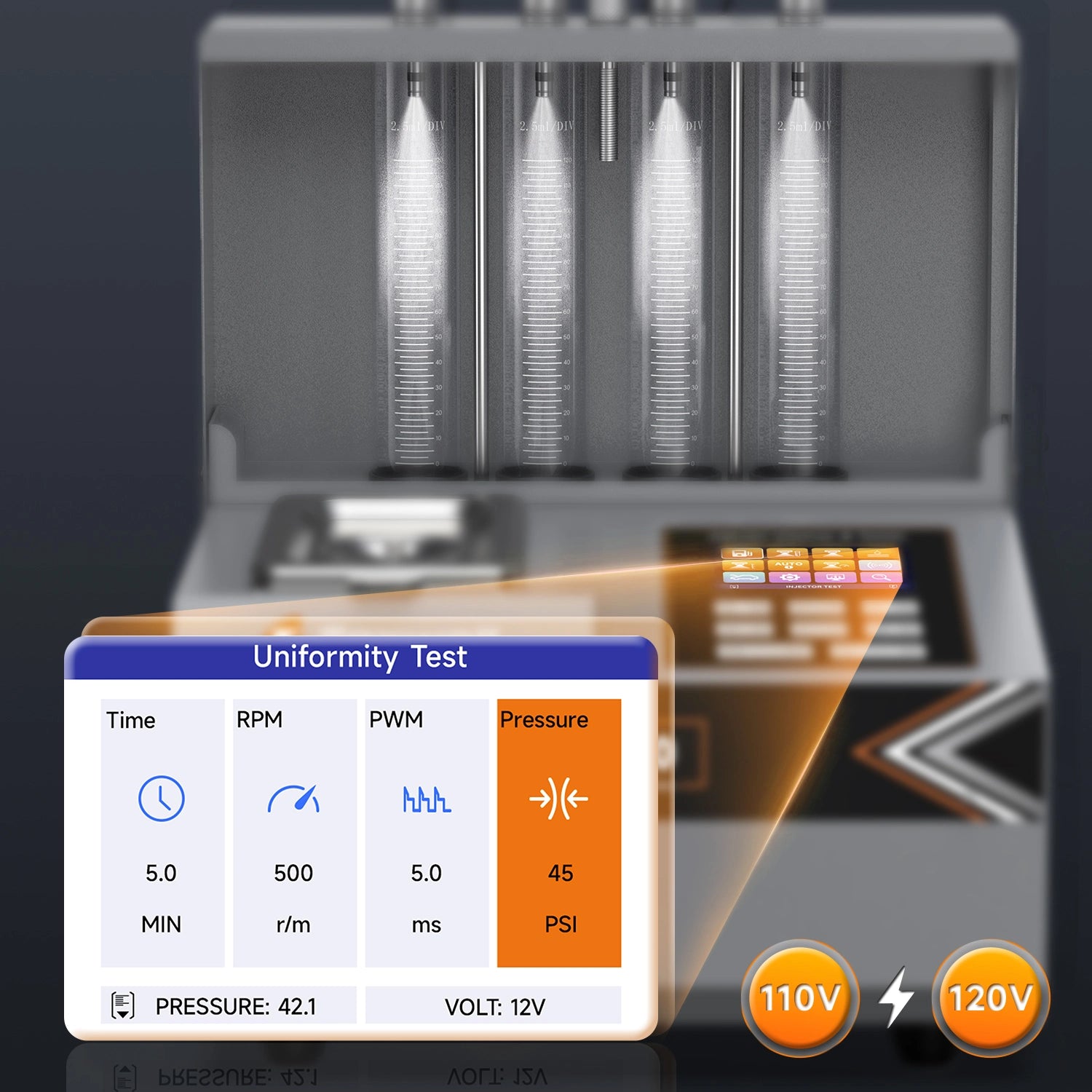

Uniformity Test

To test the uniformity of injecting amount of each injector.

If your vehicle experiences a lack of power and slow throttle response at high speeds, it is likely due to uneven fuel injection caused by a faulty injector. You can use the JT400 for uniformity testing to identify the issue and take corrective action.

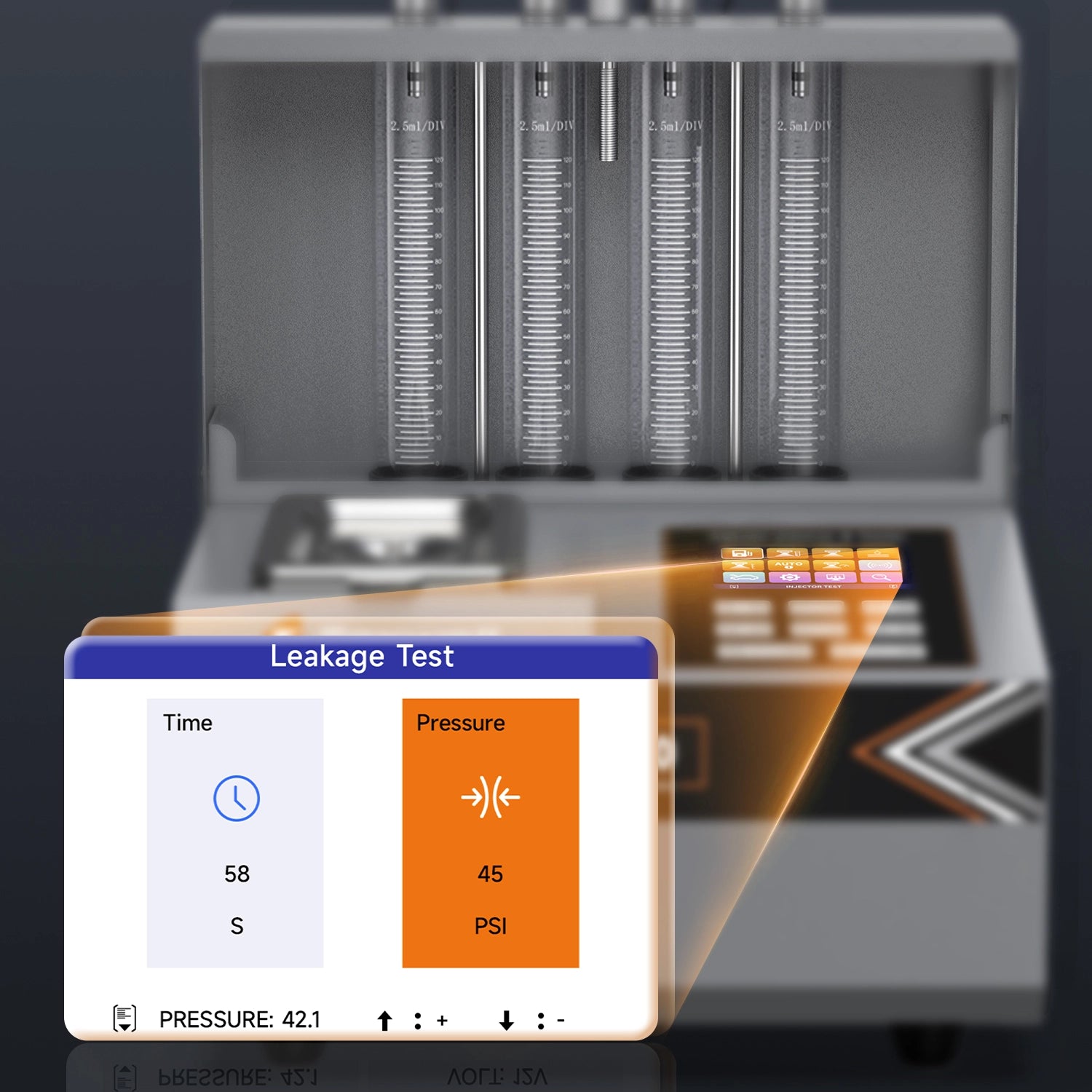

Leakage Test

To test the sealing and dribbling conditions of injectors under high pressure.

If your car emits a strange smell during startup and exceeds emissions standards, the leakage test can help detect fuel leakage caused by worn injector seals. Replacing or repairing the injectors typically resolves this issue.

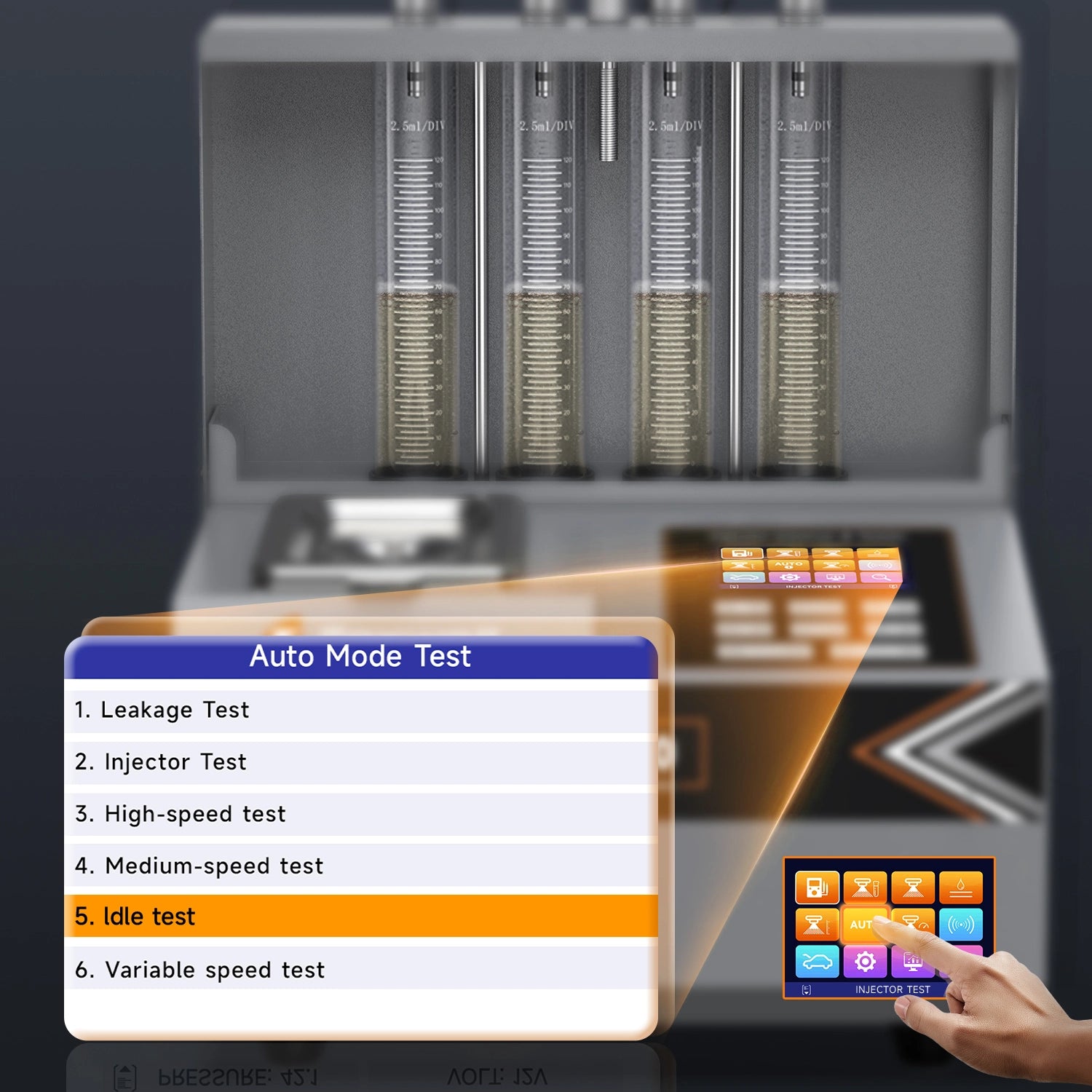

Auto Mode Test

Inspect the injectors according to the established program1 of the equipment.

For fleet managers needing to inspect multiple vehicles' injectors, the auto mode test allows the equipment to automatically check each injector according to a preset program, saving significant time and improving efficiency. The results are quickly delivered, helping technicians address specific issues.

Equipment Details